Fabrication Labs

Developing and deploying small-scale advanced fabrication labs.

Key Impact

Technologies Used

Project Brief

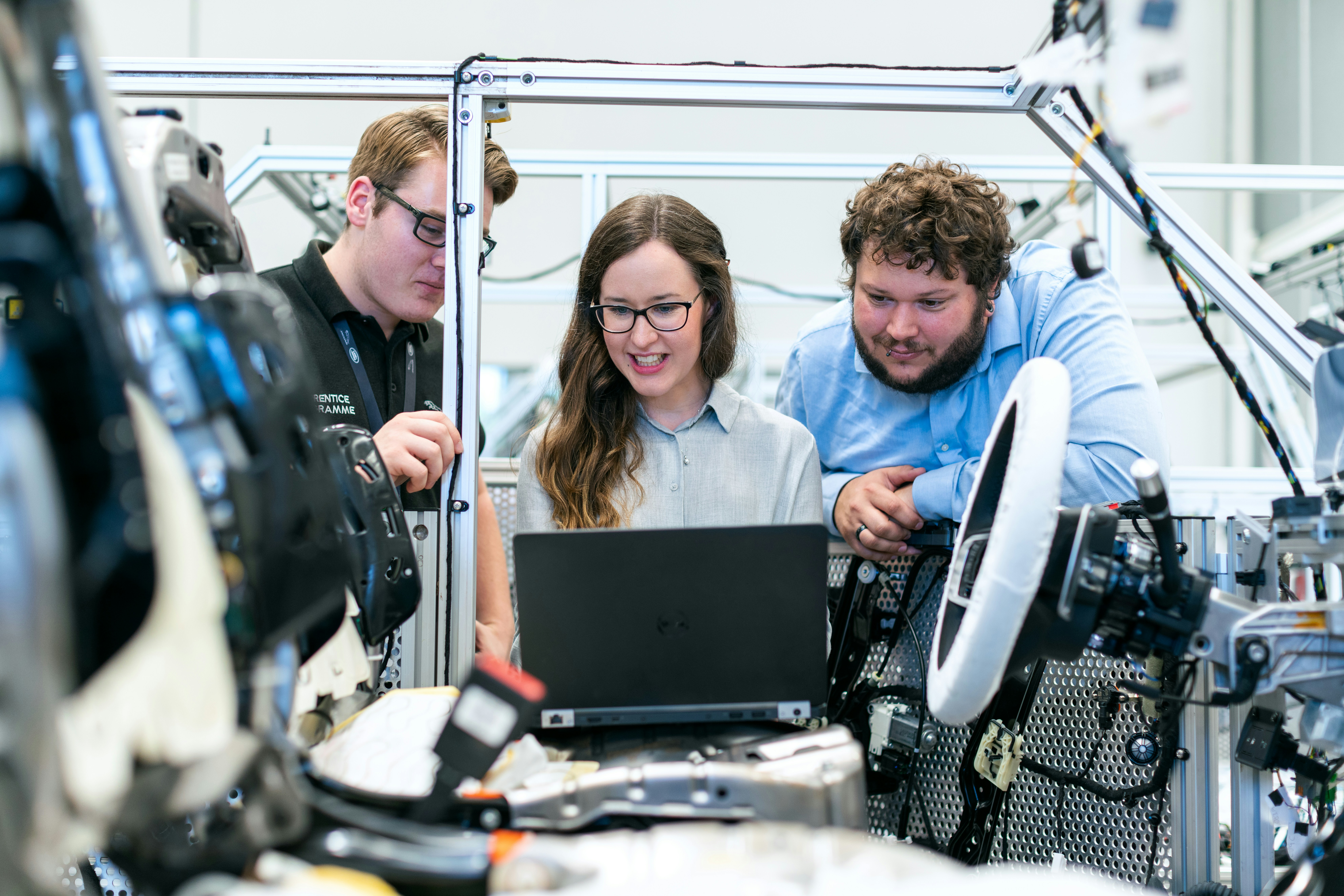

Deployment and continuous refinement of small-scale, high-density advanced fabrication labs leveraging technologies such as 3D printing and CNC machinery. Notable deployments span diverse industries and operational environments.

Challenges

Solution

In my time, I have designed small to medium scale fabrication labs primarily utilizing 3D printing and small footprint CNC machines in a variety of environments such as universities, libraries, my own production businesses, home-labs, and more. Each deployment has iterated over the previous generation of technologies and operation models.

Notable deployments and engagements:

1. 3DPX | Chicago, 2013 - The world's first retail 3D printing production service with a mixture of 20 machines including FDM, SLA, and industrial SLS equipment.

2. Manulith | Detroit, 2015 - My product development business servicing automotive, medical, and aerospace clients with custom built FDM machines.

3. Studio Roboto | New York, 2022 - An opportunity to work with one of the legends of the 3D printing industry, Rob Steiner, to set up a mid-scale art production studio with 12 Bambu Lab machines, a large industrial one cubic meter FDM machine, laser cutting, and an extensive array of post processing studio space.

4. Homelab | Detroit, New York, Chicago - In every city I have lived in, I have built a micro scale fabrication lab fitted with various tech and layouts. The latest iteration inside of a 10x10 home-office includes x4 custom Bambu Lab machines, x2 DLP machines, custom air filtration, robust high-end networking and computing, adequate work surfaces and tooling, in conjunction with the AI homelab and datacenter.

Future Development

For hard to reach places in the world such as disaster and combat zones, I would like to design and deploy multiple demonstrator configurations for various sized shipping containers, trucks, or bunker deployments. An application layer should be implemented to generatively kit out a configurable solution depending on mission parameters and logistics. My unique experience in deploying small labs, training, documentation, and living in one, would uniquely position me to tackle the challenge.

Categories

Featured Projects

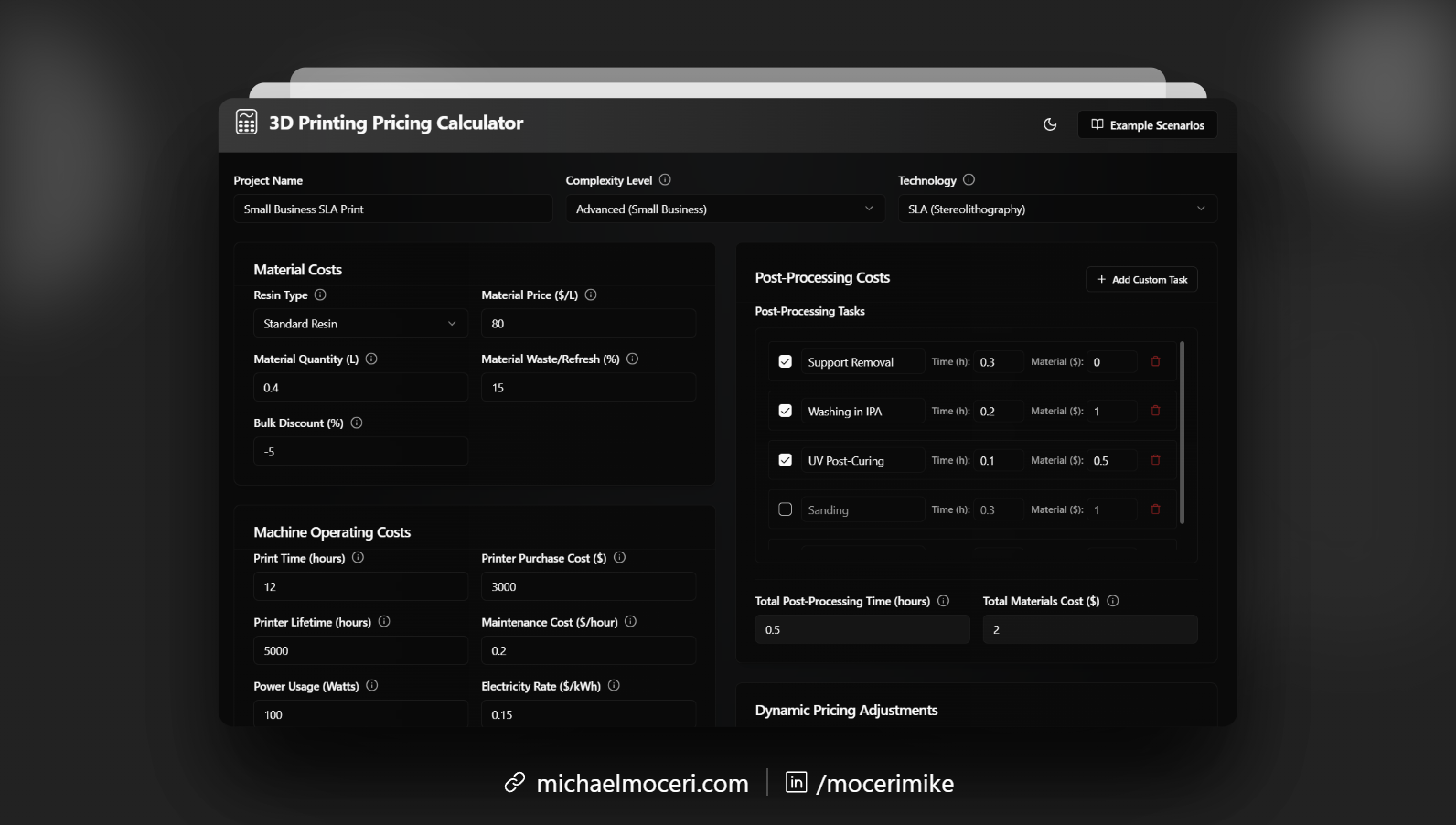

3D Printing Pricing Calculator

An intuitive 3D printing pricing tool for revenue generating businesses with varying levels of complexity.

Local AI Inference Server

A local AI application development server and network in my lab with custom configured hardware and software stack.

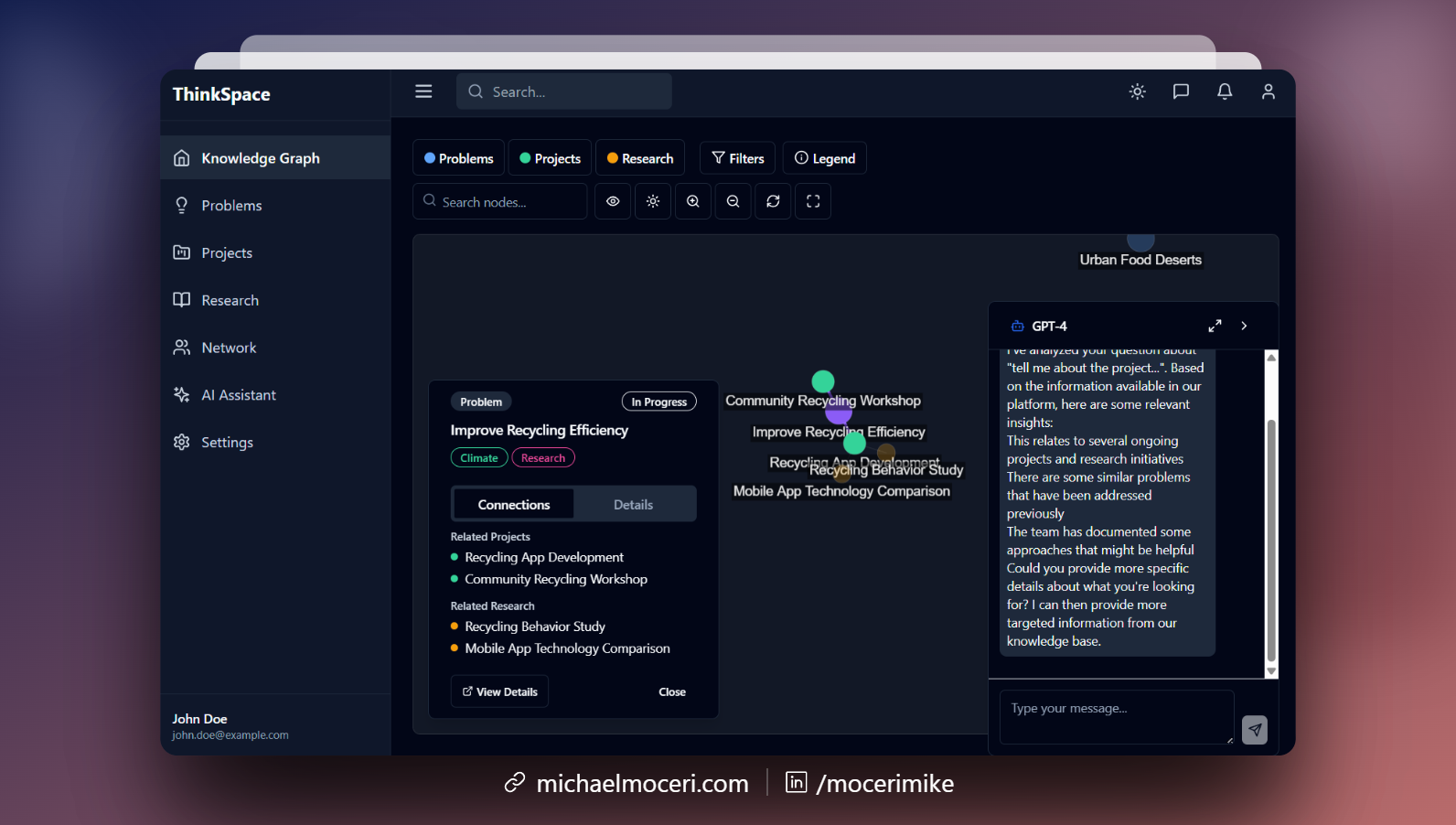

AI Research Platform

Developing and prototyping advanced agent-driven, human-in-the-loop workflows to collaboratively leverage collective intelligence.

Related Projects

art.config

Exploring the possibilities between advanced manufacturing, AI generative media creation, and fine art production.

Playboy Magazine Cover

Collaborative project with one of the most recognizable brands in the world.

Sustainable 3D Printing Challenge

Strategic consulting initiative to guide a major European automotive OEM in integrating advanced 3D printing solutions and AI-driven processes.

AI, Advanced Manufacturing, Strategy, and Entrepreneurship

© 2025 Michael Moceri. All rights reserved.